If you’re a farmer or someone who regularly operates a tractor, you may have heard of a feature called draft control. This technology is an important part of modern tractors and can greatly improve your efficiency when working on tasks like plowing, tilling, or seeding.

Draft control is a hydraulic system that adjusts the position of the implement being pulled based on the resistance it encounters while working. This allows the tractor to maintain a consistent depth or level of the implement in the ground, regardless of variations in soil conditions or terrain.

In this blog post, we’ll take a closer look at draft control on a tractor, how it works, and the benefits it can provide. We’ll also discuss some common issues that may arise when using draft control and provide tips on troubleshooting them. Whether you’re new to farming or a seasoned pro, understanding draft control is an important part of getting the most out of your tractor and improving your farming efficiency.

How does a draft sensor work?

A draft sensor is an essential component of a tractor’s draft control system. It works by measuring the amount of force or resistance encountered by an implement as it moves through the soil. The sensor is usually mounted on the lower link arms of the tractor’s three-point hitch, where it can detect changes in the amount of force required to pull an implement through the soil.

When the tractor is in operation and the implement encounters varying levels of soil resistance. The draft sensor sends signals to the tractor’s hydraulic system, which adjusts the position of the implement to maintain a consistent depth or level. This is particularly useful when tilling, planting, or harvesting, as it allows for precise control over the depth and spacing of the implements.

The draft sensor can be calibrated to specific soil conditions. It can also be adjusted to accommodate different types of implements. Some draft sensors also have the capability to measure ground speed and implement slip. It can be useful in adjusting the tractor’s speed and torque for maximum efficiency and fuel economy.

What are the Top 5 Benefits of Using Draft Control on Your Tractor

The following are the benefits of using draft control:

Improved Efficiency:

One of the most significant benefits of using draft control on your tractor is improved efficiency. With draft control, you can maintain a consistent depth or level of the implement. It can help reduce the amount of time and energy required to adjust the implement manually. This can save you time and effort, allowing you to complete your work more efficiently.

Reduced Risk of Damage:

Another significant benefit of using draft control is that it can reduce the risk of damage to your tractor and implement. When working with implements like plows or tillers, it’s essential to maintain a consistent depth or level to avoid damaging the implement or tractor. Draft control can help ensure that the implement stays at the correct depth or level. It reduces the risk of damage and helps you get the job done more safely and effectively.

Improved Consistency:

Draft control can also help you achieve more consistent and accurate results when working with implements. By maintaining a consistent depth or level, you can ensure that your work is done uniformly, reducing the risk of uneven growth or planting. This can result in better crop yields and less wasted effort.

Better Fuel Efficiency:

Another benefit of using draft control is that it can help improve your fuel efficiency. By maintaining a consistent depth or level, you can reduce the amount of drag on the implement. In this way, it helps reduce the amount of fuel required to operate your tractor.

Increased Productivity:

Draft control can help increase your productivity by allowing you to work more efficiently and effectively. With draft control, you can get the job done more quickly and accurately. It allows you to move on to other tasks and increase your overall productivity.

What is the difference between position control and draft control?

Position control and draft control are two different hydraulic systems commonly found on tractors. They have distinct differences in how they operate.

| Position Control | Draft Control |

| Used for controlling the height or depth of an implement attached to the tractor, such as a mower or a plow. | Used for controlling the amount of downward force exerted by an implement attached to the tractor, such as a cultivator or a harrow. |

| Maintains a constant height of the implement above the ground, regardless of variations in terrain or soil conditions. | Maintains a constant pressure on the ground with the implement, regardless of variations in soil conditions. |

| The operator sets a target height for the implement, and the system adjusts the hydraulic system to maintain that height. | The operator sets a target pressure for the implement, and the system adjusts the hydraulic system to maintain that pressure. |

| Position control is suitable for applications where maintaining a consistent height is important, such as mowing or grading. | Draft control is suitable for applications where maintaining a consistent downward force is important, such as cultivation or soil preparation. |

| In position control, the tractor’s hydraulic system responds to changes in the position of the implement by adjusting the height of the implement. | In draft control, the tractor’s hydraulic system responds to changes in the resistance of the implement by adjusting the downward pressure of the implement. |

How to Troubleshoot Common Draft Control Issues on Your Tractor

We will discuss some common draft control issues and how to troubleshoot them.

Implement not staying at the desired depth:

If the implement is not staying at the desired depth, the first thing to check is the hydraulic oil level. If the oil level is low, it can cause the hydraulic system to malfunction. Also, check the control valve and make sure it is not stuck or damaged. Finally, check the hydraulic cylinder and make sure it is functioning correctly and is not leaking.

Implement bouncing or vibrating:

If the implement is bouncing or vibrating, it could be due to a few different issues. First, check the hydraulic oil level and make sure it is sufficient. If the oil level is okay, the issue could be due to a malfunctioning control valve or hydraulic cylinder. Also, check the implement itself and make sure it is properly balanced.

Implement not lifting:

If the implement is not lifting. First, check the hydraulic oil level and make sure it is sufficient. Also, check the control valve and make sure it is functioning correctly. If the control valve is functioning correctly, the issue could be due to a malfunctioning hydraulic cylinder.

Implement not lowering:

If the implement is not lowering, the first thing to check is the hydraulic oil level. If the oil level is sufficient, the issue could be due to a malfunctioning control valve or hydraulic cylinder.

Implement drifting:

If the implement is drifting, it could be due to a few different issues. First, check the hydraulic oil level and make sure it is sufficient. Also, check the control valve and make sure it is not damaged or sticking. If the control valve is functioning correctly, the issue could be due to a worn or damaged hydraulic cylinder.

How to Adjust Draft Control for Different Implements?

Here are some general steps to adjust draft control for different implements:

Determine the implement’s weight and the desired depth or level:

Before adjusting the draft control, determine the implement’s weight and the desired depth or level you want it to maintain. This will help you make the necessary adjustments to the system.

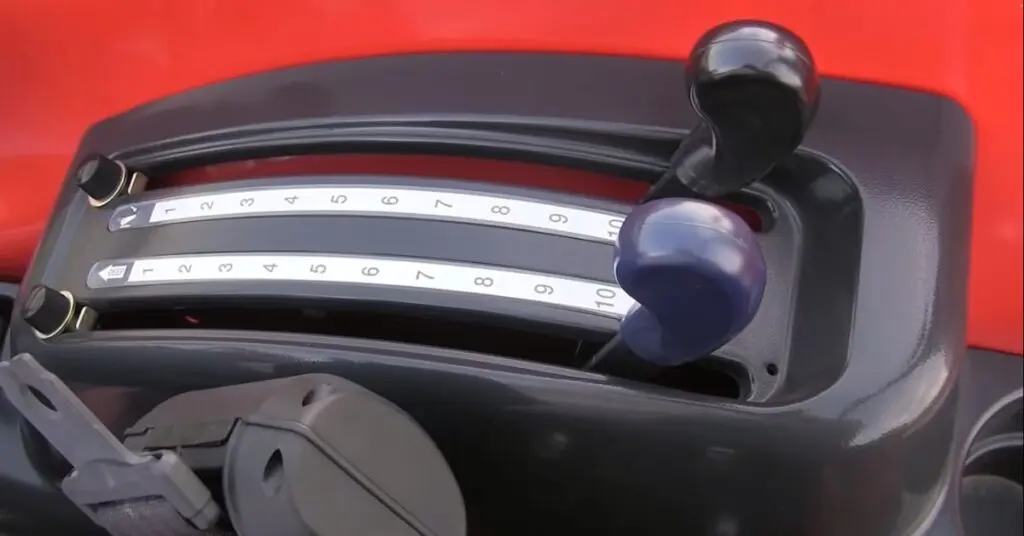

Adjust the draft control lever:

The draft control lever is usually located on the tractor’s hydraulic control panel. Adjust the lever to the desired position for the implement you’re using. For heavy implements, adjust the lever to a higher position to maintain a consistent depth. For lighter implements, adjust the lever to a lower position.

Adjust the draft control sensitivity:

Some tractors have a sensitivity adjustment for the draft control system. This adjustment allows you to set the system’s response to changes in ground resistance. For heavy soil conditions, increase the sensitivity to maintain a consistent depth. For lighter soil conditions, decrease the sensitivity.

Test the draft control system:

Once you’ve made the necessary adjustments, test the draft control system to ensure it’s working properly. Attach the implement to the tractor and start working. If the implement is maintaining the desired depth or level, the adjustments you made were successful.

Make additional adjustments if necessary:

If the implement is not maintaining the desired depth or level, make additional adjustments to the draft control system until it’s working correctly.

Conclusion

Draft control is a hydraulic system on a tractor. It allows for the precise adjustment of the position and depth of an implement based on the level of draft or resistance encountered by the implement in the soil. The system uses a draft sensor or load cells to measure the resistance encountered by the implement and then adjusts the hydraulic system accordingly to maintain a consistent depth or level.

With the advent of new technologies, draft control systems have evolved from manual to automatic. It offers greater efficiency and precision. While there are some drawbacks associated with draft control, its benefits outweigh the disadvantages, making it a critical component of modern-day farming equipment.

FAQs

What is the purpose of draft control on a tractor?

Draft control is used to maintain a consistent level of draft or resistance encountered by an implement in the soil. This allows for precise control over the position and depth of the implement. It results in improved crop yield and reduced input costs.

What are some common issues with draft control on a tractor?

Common issues with draft control include improper calibration, soil compaction, and implement wear. These issues can be mitigated by regularly calibrating the system and using the appropriate implement for the soil conditions.

Can draft control to be used with all types of implements?

Draft control can be used with most types of implements. It is important to calibrate the system to the specific implement and soil conditions to avoid soil compaction and implement wear.

Is draft control necessary for small-scale farming operations?

While draft control is not necessary for small-scale farming operations, it can still provide benefits in terms of improved crop yield and reduced input costs.